Moving Towards Sustainable Growth

Transforming agricultural waste into premium biomass pellets, generating carbon credits, and creating a sustainable energy ecosystem for a cleaner tomorrow.

Tarunati Industries Private Limited

Pioneering sustainable solutions for a greener tomorrow through innovative agricultural waste management and carbon credit generation.

Our Mission

Driving Sustainable Energy from Agricultural Waste - Converting cotton stalks into high-quality biomass pellets while generating valuable carbon credits, minimizing stubble burning, and creating economic opportunities for farmers and energy providers across India.

Our Vision

To be India's leading sustainable energy company transforming agricultural waste into clean power, making significant environmental impact through carbon offset programs and creating substantial value for stakeholders.

Meet Our Founders

Vivek Merugu

BTech NITW

Co-Founder & CTO

Technical Innovation & Process Engineering

Passionate entrepreneur with strong technical background from NIT Warangal, dedicated to sustainable innovation and environmental conservation through cutting-edge biomass technology solutions.

Dhanush Chandra Kasarapu

BTech NITW | MBA IIMK

Co-Founder & CEO

Strategic Planning & Business Development

Combines technical expertise from NIT Warangal with business acumen from IIM Kozhikode, driving strategic growth and market development in renewable energy and carbon trading sectors.

The Agricultural Waste Crisis

Environmental & Economic Challenges

- 15-18 lakh tons of agricultural waste burned annually in Telangana

- Cotton stalk burning creates severe air pollution in rural communities

- Stubble burning contributes up to 35% of Delhi's winter air pollution

- Releases harmful CO₂, PM2.5, CO, and NOx emissions

- Reduces soil fertility and damages agricultural ecosystems

- Wasted biomass potential of 30-35 lakh tons annually in Telangana alone

Our Innovative Solution

Premium Cotton Stalk Pellets

Converting 15,000 tons of cotton stalks annually into high-energy biomass pellets with exceptional 4095 kcal/kg calorific value for optimal power generation efficiency.

Power Plant Co-firing Compliance

Supporting government mandates for 5-10% biomass co-firing in thermal power plants, ensuring regulatory compliance and sustainable energy production for 71+ TPPs.

Carbon Credits Revenue

Eligible for CCTS 2023 carbon credit programs generating Rs. 2-3 crores additional annual revenue through verified emission reductions and offset mechanisms.

Zero Net Carbon Footprint

Completely carbon neutral process - CO₂ released during combustion is naturally absorbed in the next crop cycle, creating true sustainability.

Carbon Credits Monetization Strategy

Generating substantial additional revenue through verified carbon offset programs and emission trading mechanisms.

CCTS 2023 Eligibility

Fully compliant with Carbon Credit Trading Scheme 2023 guidelines, enabling participation in India's official carbon trading mechanism with verified emission reduction credits.

Voluntary Carbon Markets

Access to private enterprises and individual carbon offset buyers seeking verified emission reductions for their sustainability goals and net-zero commitments.

Financial Benefits

Rs. 2-3 crores additional annual revenue through carbon credit sales, representing 20-25% of total project revenue and enhancing overall profitability.

Carbon Trading Mechanism

Client Benefits & Market Advantages

🏭 Thermal Power Plants

- Earn carbon credits through biomass co-firing

- Avoid penalties for emission targets

- Meet regulatory compliance requirements

- Reduce overall carbon intensity

International Standards

- Verified Carbon Standard (VCS) compliance

- Gold Standard certification eligibility

- ISO 14064 greenhouse gas accounting

- Third-party verification processes

Market Opportunities

- Growing corporate sustainability demands

- Government emission reduction mandates

- International climate finance access

- Premium pricing for verified credits

Verification & Trading Process

Baseline Assessment

Establish emission baseline and measurement protocols

Production Monitoring

Continuous monitoring of pellet production and emission reductions

Third-party Verification

Independent verification of emission reduction claims

Credit Issuance

Certified carbon credits issued for verified reductions

Market Trading

Sale of credits through various trading platforms and direct buyers

Technical Excellence & Specifications

Superior quality specifications meeting international standards for biomass fuel applications and carbon credit requirements.

Daily Production Capacity

40 tons/day

24/7 continuous operations

Annual Production

12,000 tons

Consistent year-round output

Calorific Value

4095 kcal/kg

Exceptional energy content

Raw Material Input

15,000 tons

Cotton stalks annually

Pellet Diameter

6-12 mm

Optimal combustion size

Ash Content

<8%

Low residue premium grade

Moisture Content

<14%

Optimal storage stability

Bulk Density

1120 kg/m³

Efficient transportation

Advanced Manufacturing Equipment

Collection & Preprocessing

Advanced cotton stalk collection equipment for efficient raw material gathering and initial processing preparation.

Hammer Mill System

High-efficiency grinding operations for optimal particle size reduction and consistent pellet quality preparation.

Rotary Dryer

Precision moisture control system ensuring optimal moisture content for superior pellet formation and stability.

Ring Die Pellet Mill

High-efficiency pelletizing system producing consistent, high-density pellets with superior binding characteristics.

Automated Screening & Packaging

Quality control screening and automatic packaging systems ensuring product consistency and efficient distribution.

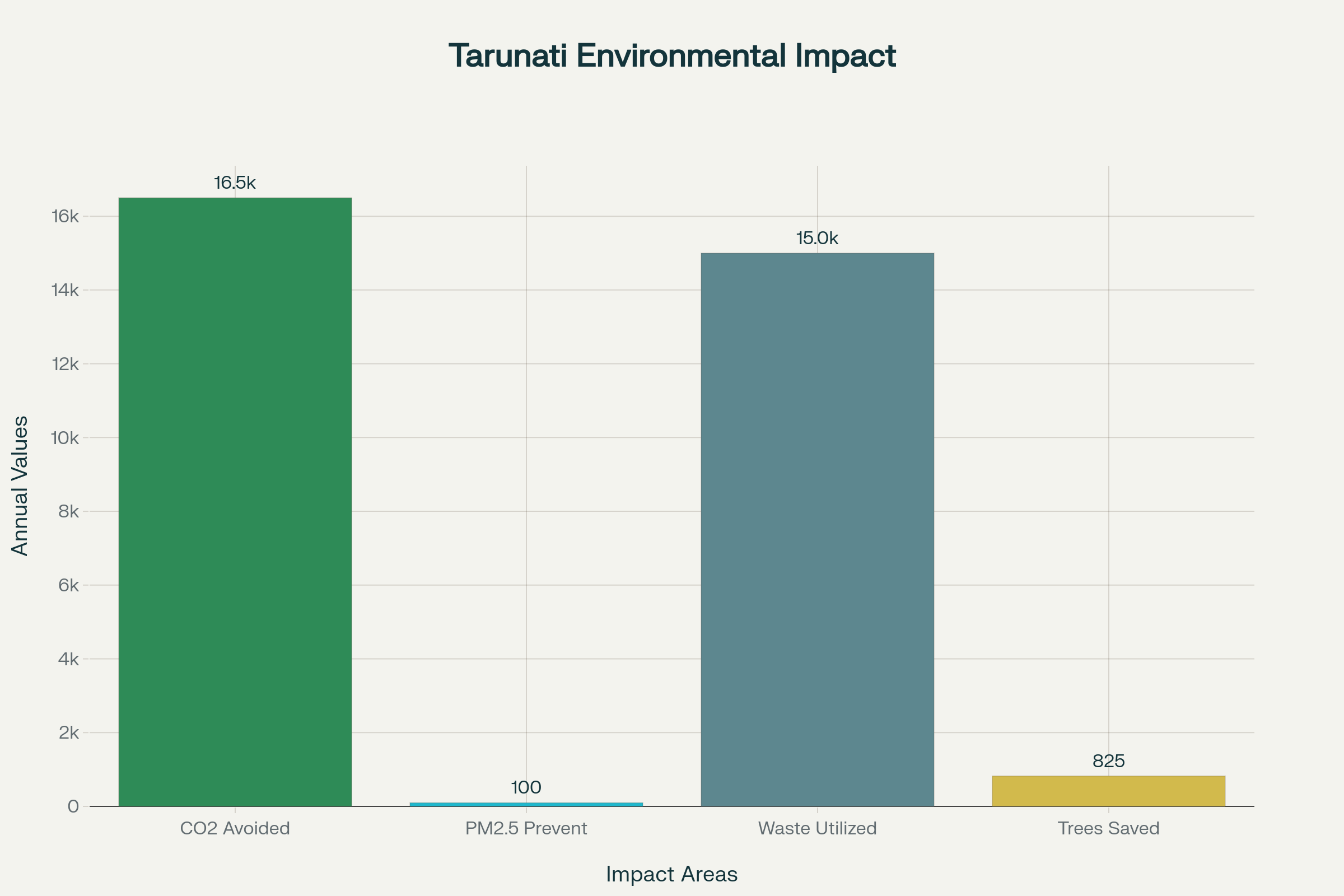

Quantified Environmental Impact

Measurable positive environmental benefits through agricultural waste utilization and emission reduction.

CO₂ Emissions Avoided

15,000-18,000 tons annually

Equivalent to removing 3,000+ cars from roads annually through biomass substitution for fossil fuels.

PM2.5 Prevention

~100 tons annually

Significant reduction in particulate matter emissions improving air quality in rural and urban areas.

Waste Utilization

15,000 tons cotton stalks

Converting agricultural waste into valuable energy resource, preventing open field burning.

Forest Conservation

750-900 trees equivalent

Biomass energy reducing pressure on forest resources and supporting biodiversity conservation.

Regional Environmental Benefits

Telangana Impact

Reducing state's 66.56 Mt CO₂e emissions through sustainable biomass utilization and stubble burning prevention.

Air Quality Improvement

Reducing PM2.5, NOx, and black carbon emissions contributing to cleaner air in agricultural regions.

Soil Health

Preventing soil nutrient loss and degradation caused by traditional agricultural waste burning practices.

Massive Market Opportunity

Unprecedented growth potential in India's rapidly expanding biomass energy sector with strong government support and carbon trading mechanisms.

Cotton Production Leadership

Telangana ranks 3rd in cotton production with 44.78 lakh acres under cultivation, providing abundant raw material supply chain.

Biomass Co-firing Mandate

Government mandate increasing from 5% to 10% biomass co-firing, creating massive demand for quality pellets.

Market Size Potential

Serviceable Available Market (SAM) of ₹28,000-35,000 crores for biomass pellet manufacturers with robust growth trajectory.

Investment Opportunity

Attractive returns through dual revenue streams, government support, and rapidly growing market demand.

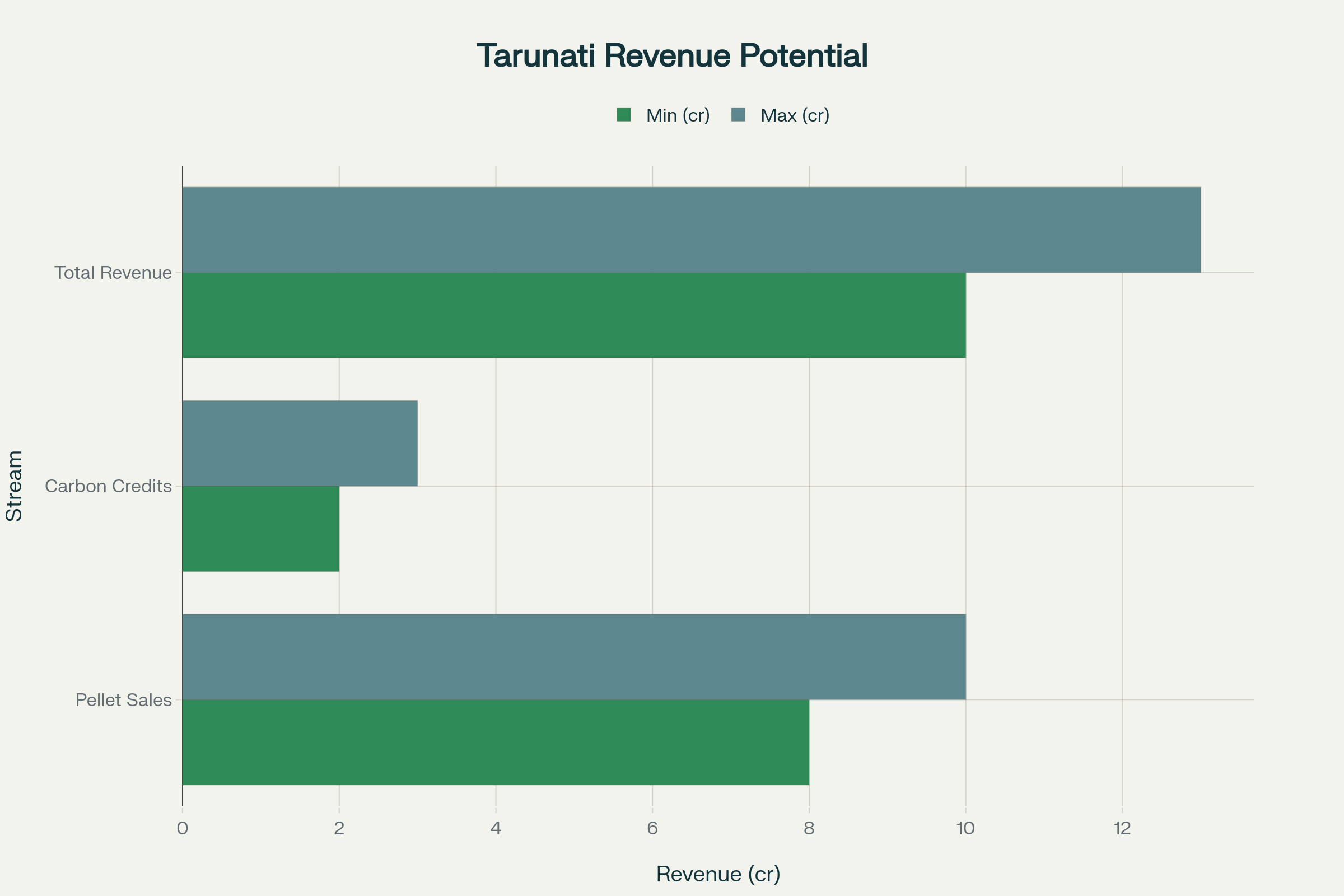

Primary Revenue Stream

Rs. 1-3 crores annually

Biomass pellet sales to thermal power plants with guaranteed off-take agreements and competitive pricing.

Carbon Credit Revenue

Rs. 1-2 crores annually

Additional income through CCTS 2023 eligible carbon credit trading and voluntary market participation.

Total Revenue Potential

Rs. 2-5 crores annually

Combined revenue streams providing robust cash flows and attractive investment returns.

Key Investment Metrics

Quick ROI

Rapid return on investment with payback period optimized through dual revenue streams and government incentives.

Attractive IRR

Internal Rate of Return demonstrating strong project viability and investor value creation potential.

Robust Profitability

Strong gross profit margins with efficient operations scaling to robust net profitability by Year 3.

Government Support

MNRE schemes, TSREDCO guidance, and policy framework ensuring favorable business environment.

Join the Renewable Energy Revolution

Partner with Tarunati Industries for exceptional returns, positive environmental impact, and participation in India's clean energy transformation.

Strategic Location - Khammam, Telangana

Perfectly positioned for optimal supply chain efficiency, market access, and operational excellence.

Local Expertise & Heritage

Both founders are natives of Khammam with deep understanding of regional agriculture, local business landscape, farmer networks, and community relationships built over decades.

Abundant Raw Material Supply

Khammam is the largest cotton-producing district in Telangana, ensuring consistent, high-quality cotton stalk supply throughout the year with proximity to 44.78 lakh acres under cultivation.

Superior Infrastructure Connectivity

Excellent transportation network with National Highways, major railway connections, and port access providing seamless logistics for raw material procurement and product distribution.

Power Plant Proximity

TSGENCO power plants within 120 km radius, all Telangana TPPs within 200 km, ensuring minimal transportation costs, optimal delivery times, and strong customer relationships.

Government Support

TSREDCO technical guidance, state policy support, environmental clearances facilitation, and access to renewable energy incentive schemes and financial assistance programs.

Cost Efficiency

Lower operational costs through reduced transportation expenses, competitive land prices, available skilled workforce, and proximity to both suppliers and customers.

Partner with Tarunati Industries

Join us in building a sustainable future and capitalizing on the renewable energy revolution with carbon credit monetization.

For Power Plants & Energy Companies

Looking for reliable biomass pellet supply to meet government co-firing mandates and carbon reduction targets? We offer consistent quality, competitive pricing, guaranteed delivery schedules, and carbon credit support.

Request Supply QuoteFor Investors & Financial Partners

Join the renewable energy revolution with exceptional returns through dual revenue streams (pellets + carbon credits), strong market potential, government support, and significant environmental impact.

Investment InquiryGeneral Contact & Information

Location: Khammam, Telangana 507003, India

Primary: hello@tarunatiindustries.com

Investors: hello@tarunatiindustries.com

Phone: +91-9959509808

Website: www.tarunatiindustries.com